Self laminating wrap around cable labels are designed to provide durable and reliable identification for cables in demanding environments. These labels feature a wrap-around design with a protective laminate that shields the printed information from wear, moisture, chemicals, and UV exposure. They are essential for maintaining organized and safe wiring systems across industrial, commercial, and IT applications.

This article explores the features, applications, and benefits of self laminating wrap around cable labels.

What Are Self Laminating Wrap Around Cable Labels?

Self laminating wrap around cable labels are specialized labels that wrap around the circumference of a cable. The printed portion is protected by a clear lamination, ensuring that text, numbers, and barcodes remain legible over time. These labels are commonly used for:

- Electrical wiring and control panels

- Data centers and server racks

- Industrial machinery and automation systems

- Telecommunications and network cables

- Utility and energy infrastructure

Key Features of Self Laminating Wrap Around Cable Labels

Durable Lamination

The lamination layer protects printed information from abrasion, moisture, chemicals, and UV exposure, ensuring long-lasting readability.

Easy Application

The wrap-around design allows the label to be quickly wrapped around cables, securing it in place without the need for complex tools.

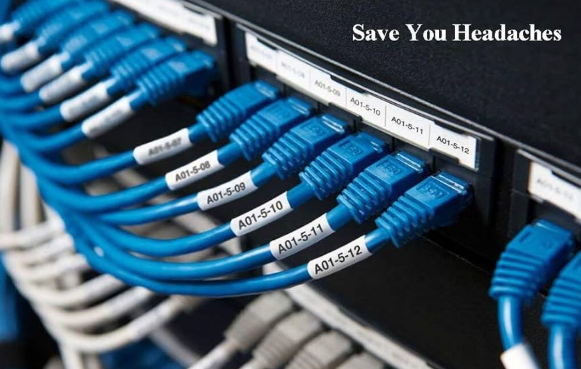

Clear and Scannable

High-quality printing ensures legible text, numbers, and barcodes that are easy to scan and identify.

Cable Versatility

Available in various sizes, these labels self laminating wrap around cable labels are compatible with multiple cable diameters, including fiber optic, electrical, and network cables.

Customization Options

Labels can be printed with letters, numbers, symbols, or barcodes to meet specific project or organizational requirements.

Applications Across Industries

Electrical and Industrial

Used in control panels, machinery, and industrial environments to clearly identify wiring and reduce maintenance errors.

Data Centers and IT

Label network and power cables to organize server racks, simplify troubleshooting, and prevent misconnection.

Telecommunications

Fiber optic and network cables can be labeled for accurate installation, maintenance, and upgrades.

Utilities and Energy

Marking cables in substations, power distribution, and monitoring systems enhances safety and compliance.

Office and Commercial Spaces

Organize office network cables, AV systems, and equipment with clear, durable wrap-around labels.

Benefits of Using Self Laminating Wrap Around Cable Labels

Long-Term Durability

The laminate protects the label from environmental factors, ensuring the printed information lasts over time.

Improved Organization

Clearly labeled cables simplify maintenance, reduce errors, and support structured wiring systems.

Time and Cost Efficiency

Quick application and long-lasting durability reduce the need for frequent replacements and maintenance efforts.

Compliance and Safety

High-quality labels help meet industry standards and regulatory requirements for cable identification.

Versatility

Suitable for various cable types, diameters, and applications with customizable labeling options.

Choosing the Right Self Laminating Wrap Around Cable Labels

Consider the following when selecting labels:

- Cable type and diameter

- Environmental resistance (heat, moisture, chemicals, UV)

- Label size and lamination style

- Printing clarity and customization needs

- Compliance with industry standards

- Ease of application

Selecting the right self laminating wrap around cable labels ensures efficient, professional, and reliable cable management.

Conclusion

Self laminating wrap around cable labels are a durable, versatile, and protective solution for cable identification across industries such as electrical, data centers, telecommunications, and utilities. Their wrap-around design and lamination layer provide long-lasting legibility, enhance organization, and reduce errors in complex wiring systems.

Investing in self laminating wrap around cable labels ensures accurate, safe, and professional cable management in demanding environments.

See also: Revolvertech .Com: Revolvertech.Com: the Future of Digital Technology

Frequently Asked Questions About Self Laminating Wrap Around Cable Labels

What are self laminating wrap around cable labels used for?

They are used to identify and protect cables in industrial, electrical, IT, telecommunications, and utility environments.

Are they durable?

Yes, the laminate protects against abrasion, moisture, chemicals, and UV exposure for long-lasting use.

Can they fit different cable sizes?

Yes, they come in various sizes suitable for multiple cable diameters.

How are they applied?

They are wrapped around cables and secured with the self-laminating layer without damaging the cable.

Which industries benefit most from these labels?

Electrical, industrial automation, data centers, telecommunications, utilities, and office environments benefit from self laminating wrap around cable labels.