Introduction

In metal fabrication, press brakes are essential machines for bending and shaping sheet metal with accuracy and consistency. Their applications span across automotive, aerospace, construction, and general manufacturing industries. While press brakes increase efficiency and precision, operating them correctly requires skill, attention to detail, and adherence to safety protocols. Understanding how to use a press brake effectively is crucial for both beginners and experienced operators. This article provides a comprehensive guide on press brake operation, safety measures, and best practices to achieve accurate results while minimizing risks.

Understanding Press Brakes

Types of Press Brakes

Press brakes come in several configurations, each suitable for specific tasks:

- Manual Press Brakes: Require manual adjustments and operator skill to perform bends.

- Hydraulic Press Brakes: Use hydraulic pressure to move the ram, allowing more powerful and consistent bends.

- CNC Press Brakes: Computer-controlled machines that provide precise control over angles, depth, and bending sequences, ideal for complex and repetitive tasks.

Understanding the type of press brake you are working with is essential for proper operation and programming.

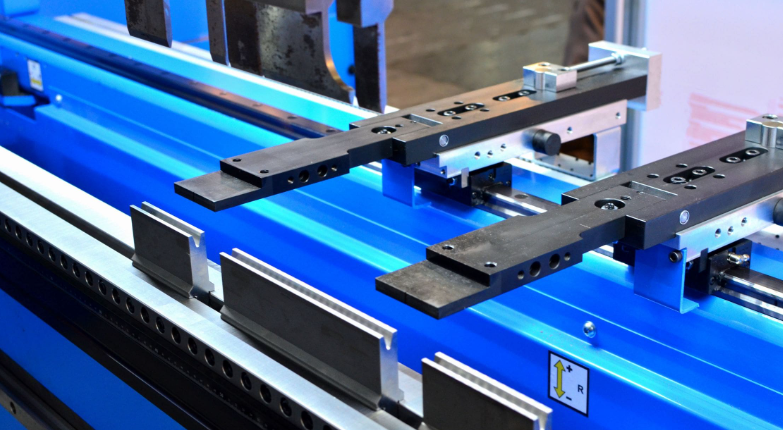

Key Components

Familiarity with the main components is critical to safe and effective operation:

- Ram or Punch: The moving component that presses the metal into shape.

- Die: The stationary part that forms the metal during bending.

- Back Gauge: Ensures consistent placement of the metal sheet.

- Control Panel: Allows operators to input parameters and monitor the bending process.

- Safety Devices: Guards, light curtains, and emergency stops protect operators from injury.

Knowing how each part functions helps operators achieve consistent bends and maintain workplace safety.

Preparation for Operation

Safety Measures

Before starting any bending operation, operators must prioritize safety. Essential steps include:

- Wearing personal protective equipment such as safety glasses, gloves, and steel-toed shoes.

- Checking that all machine guards and emergency stops are functional.

- Reviewing the operation manual and company safety protocols.

A proactive approach to safety minimizes the risk of accidents and injuries.

Material and Tooling Setup

Proper preparation of the workpiece and tooling is crucial:

- Select punch and die combinations suitable for the metal type and thickness.

- Ensure the metal sheet is properly positioned and secured to prevent slipping.

- Verify that the press brake settings match the specifications for the bend.

Correct setup ensures accurate results and reduces material waste.

Machine Calibration

Calibrating the press brake involves how to use a press brake adjusting the back gauge, ram, and other components according to the job requirements. Ensuring that the machine is properly calibrated improves precision and reduces the need for corrective adjustments later.

Step-by-Step Operation

Programming and Setup

For CNC or computer-assisted press brakes, programming is an essential step. Input details such as:

- Material type and thickness

- Desired bend angle and radius

- Sheet dimensions

- Tooling selection

For manual or hydraulic press brakes, operators must set the ram stroke, back gauge, and die position according to the planned bend.

Loading the Workpiece

Carefully place the metal sheet on the machine table, ensuring proper alignment with the back gauge. Flatten the sheet against the die to prevent shifting during the bending process. Proper placement is key to achieving accurate bends and preventing material damage.

Executing the Bend

Engage the press brake using the foot pedal or control switch. Operators should monitor the process closely, keeping hands and body parts away from the ram and die. For complex bends, it is advisable to execute them incrementally to maintain control and precision.

Unloading and Inspection

After the bend is complete, carefully remove the workpiece and inspect it for accuracy. Compare the bend angle and shape with the specifications. If adjustments are needed, modify the setup or program before continuing with additional pieces.

See also: HDFC Fintechasia Net: HDFC Fintechasia: Navigating Digital Financial Services

Tips for Precision and Efficiency

Bend Allowance and Material Compensation

Different metals and thicknesses bend differently. Operators should understand how to calculate bend allowance and compensation to achieve precise angles. Fine-tuning the back gauge and ram depth helps correct minor variations.

Reducing Material Waste

Plan the bending sequence strategically to minimize scrap. Using nesting techniques or adjusting the bend order can save material and time while maintaining product quality.

Maintaining Consistency

For high-volume production, consistent results are essential. Regularly monitor machine settings, tool condition, and material alignment to ensure uniform bends across multiple workpieces.

Maintenance and Troubleshooting

Routine Maintenance

Proper maintenance is vital for long-term machine performance and safety. Essential tasks include:

- Lubricating moving parts

- Inspecting dies and punches for wear or damage

- Checking hydraulic and electrical systems

- Testing safety devices and emergency stops

Regular maintenance prevents malfunctions and ensures reliable operation.

Troubleshooting Common Issues

Operators should be able to identify and correct common problems, such as:

- Misaligned Bends: Adjust back gauge or reposition the workpiece.

- Inconsistent Angles: Inspect tooling, recalibrate the machine, and check material specifications.

- Machine Malfunctions: Review programming, inspect electrical and hydraulic systems, and consult the operation manual.

Quick resolution of issues minimizes production delays and maintains quality standards.

Training and Best Practices

Comprehensive Operator Training

Effective training is crucial for safe and accurate press brake operation. Operators should learn about machine functions, safety measures, programming, and troubleshooting. Hands-on practice under supervision builds confidence and skill.

Promoting a Safety Culture

Creating a culture that emphasizes safety reduces accidents and improves overall efficiency. Encourage reporting of hazards, adherence to standard procedures, and participation in refresher courses. Regular safety meetings and performance reviews reinforce proper behavior.

Documentation and Record-Keeping

Maintaining records of programs, maintenance schedules, and inspection results helps operators reproduce successful outcomes, comply with industry standards, and implement continuous improvement.

Conclusion

Operating a press brake successfully requires a combination of technical knowledge, attention to detail, and adherence to safety protocols. Understanding machine components, preparing materials and tooling properly, programming accurately, and following operational procedures are all essential for consistent results. Routine maintenance, continuous training, and a focus on safety further enhance efficiency and precision. Mastering how to use a press brake is not just a skill—it is a commitment to quality, safety, and reliability in the metal fabrication industry.