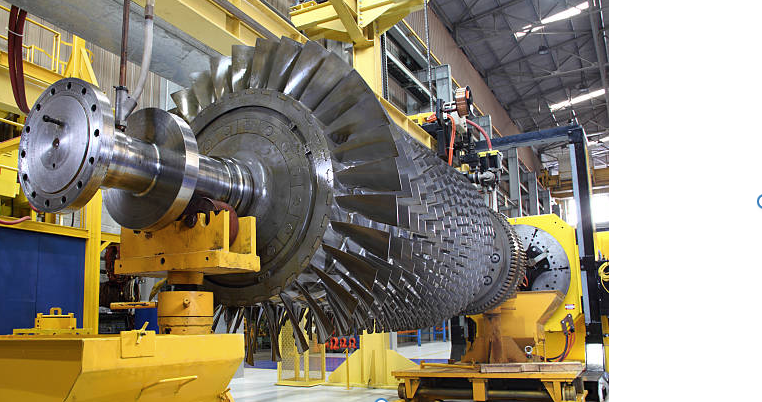

Gas turbine rotors are among the most critical and heavily loaded components in any power generation system. They transfer enormous amounts of energy from the combustion process to the generator while operating at extremely high rotational speeds and temperatures. Because rotors are subjected to constant mechanical, thermal, and environmental stresses, they gradually experience degradation that can reduce efficiency, reliability, and safety, which is why timely rotor repair is essential to maintaining long term turbine performance and operational integrity. Understanding how this damage occurs and how it can be repaired is essential for maintaining turbine performance and extending asset life.

The Role of the Gas Turbine Rotor

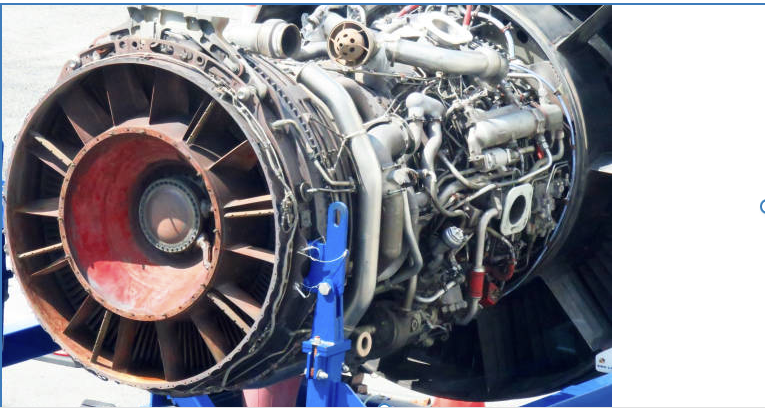

The rotor is the rotating assembly that carries turbine blades and connects to the generator. As hot gases flow through the turbine, they strike the blades mounted on the rotor, causing it to spin. This rotational motion is what ultimately produces electrical power.

Because rotors operate at thousands of revolutions per minute and endure high temperatures and loads, even minor damage can have serious consequences. Imbalances, cracks, or surface degradation can lead to vibration, efficiency losses, or catastrophic failure. For this reason, rotors require careful inspection, maintenance, and targeted repair throughout their service life.

Thermal Fatigue and Its Impact on Rotors

One of the most common damage mechanisms affecting gas turbine rotors is thermal fatigue. This occurs when components repeatedly heat up and cool down during start ups, shutdowns, and load changes. Each cycle of heating and cooling causes the metal to expand and contract. Over time, this repeated movement creates microscopic cracks in the material.

These cracks usually begin at stress concentration points such as blade attachment areas, fillets, and keyways. As the turbine continues to operate, the cracks can grow larger, eventually threatening the structural integrity of the rotor.

Thermal fatigue can lead to several problems, including.

- Reduced mechanical strength

- Increased vibration

- Risk of crack propagation and rotor failure

Targeted repair strategies for thermal fatigue typically include non destructive testing to locate cracks, followed by precision machining or welding to remove damaged material and restore structural integrity. Heat treatment is often used afterward to relieve residual stresses and improve fatigue resistance.

Erosion Caused by High Velocity Gas Flow

Erosion is another significant source of rotor damage. As hot gases move through the turbine at high speed, they carry small particles such as dust, ash, or unburned fuel. These particles strike the rotor blades and surfaces, gradually wearing away material.

Over time, erosion can change the aerodynamic profile of blades and the surface finish of the rotor. This leads to reduced efficiency because the turbine no longer channels gas flow as effectively. Erosion can also increase clearances between rotating and stationary components, reducing pressure and energy transfer.

Erosion damage typically appears as thinning of blade edges, rough surfaces, and loss of original contour. While this process is gradual, it can significantly impact turbine output if left unaddressed.

Repair strategies for erosion include material buildup using welding or thermal spray techniques, followed by precision grinding to restore original dimensions and surface smoothness. Protective coatings may also be applied to reduce future erosion and extend component life.

See also: HDFC Fintechasia Net: HDFC Fintechasia: Navigating Digital Financial Services

Corrosion in Harsh Operating Environments

Corrosion occurs when rotor materials react chemically with their environment. Gas turbines often operate in conditions where moisture, sulfur, or other corrosive elements are present in the air or fuel. These substances can attack metal surfaces, leading to pitting, oxidation, and material loss.

Corrosion weakens the rotor and can act as a starting point for fatigue cracks. It also creates rough surfaces that increase aerodynamic losses and disrupt airflow.

In coastal or industrial environments, corrosion can be especially severe. Salts and pollutants accelerate chemical reactions, making regular inspection and maintenance even more important.

Repairing corrosion damage involves removing affected material, treating the surface, and restoring it with suitable alloys or coatings. Protective coatings play a critical role in preventing further corrosion by creating a barrier between the metal and the environment.

Mechanical Fatigue and Stress

In addition to thermal fatigue, gas turbine rotors experience mechanical fatigue due to continuous rotation and fluctuating loads. Every time a turbine changes speed or load, stresses within the rotor change. Over millions of cycles, these stresses can cause fatigue damage even if temperatures remain stable.

Mechanical fatigue often shows up as cracking in high stress areas, especially near blade roots and attachment features. If not detected early, these cracks can grow and eventually compromise rotor integrity.

Advanced inspection techniques such as ultrasonic testing and eddy current testing are used to detect fatigue cracks before they become dangerous. Once identified, repairs may involve crack removal, welding, and stress relieving processes to restore strength.

The Role of Vibration and Imbalance

Rotor damage is often accompanied or accelerated by vibration and imbalance. When material is lost through erosion or corrosion, or when repairs are uneven, the rotor may no longer be perfectly balanced. This imbalance increases vibration, which in turn puts additional stress on bearings, seals, and the rotor itself.

High vibration can also worsen existing cracks and speed up fatigue damage. Therefore, balancing and alignment are essential parts of any rotor repair strategy.

After repairs are completed, rotors are dynamically balanced to ensure smooth operation. This process reduces vibration, improves efficiency, and protects both the rotor and surrounding components.

How Targeted Repairs Restore Rotor Performance

Targeted rotor repair focuses on addressing specific damage mechanisms rather than replacing the entire rotor. This approach is both cost effective and efficient.

The repair process typically begins with thorough inspection and testing to identify all areas of damage. Engineers then evaluate whether the rotor can be safely restored and which repair techniques are required.

Repairs may include.

- Welding to rebuild worn or cracked areas

- Precision machining to restore critical dimensions

- Heat treatment to relieve stresses and improve material properties

- Coating application to protect against erosion and corrosion

- Dynamic balancing to ensure smooth operation

By applying the right combination of these techniques, repair specialists can return rotors to a condition that supports reliable and efficient turbine operation.

Benefits of Proactive Rotor Repair

Proactive rotor repair offers significant advantages for turbine operators. By addressing damage early, plants can avoid costly unplanned outages and extend the life of their equipment. Restored rotors also improve turbine efficiency by maintaining proper aerodynamics and balance.

From a financial perspective, repairing a rotor is far less expensive than replacing it with a new one. It also reduces lead times, which helps plants maintain high availability and meet power demand.

In addition, proactive repair supports long term asset management by allowing operators to plan maintenance based on condition rather than waiting for failures.

Conclusion

Gas turbine rotors operate under extreme conditions that make them vulnerable to thermal fatigue, erosion, corrosion, and mechanical stress. These damage mechanisms gradually degrade performance and increase the risk of failure. However, with proper inspection and targeted repair strategies, much of this damage can be effectively reversed.

By understanding how rotors deteriorate and how modern repair techniques restore their performance, turbine operators can make informed decisions that improve reliability, efficiency, and cost control. In a demanding energy environment, maintaining healthy rotors is a key part of keeping gas turbines running safely and profitably.